what is lateral expansion in charpy impact test|charpy impact tester table : import The amount by which the specimen deforms is measured and expressed as millimetres of lateral expansion. ASME B31.3 for example requires a lateral expansion of 0.38mm for bolting materials and steels with a UTS exceeding . Resultado da Jill decide começar sua própria fazenda no estábulo da família. Mas ela descobre que já está ocupada - por uma patinha mandona.

{plog:ftitle_list}

webFestspielhaus Hall. Flexible booking options on most hotels. Compare 1,499 hotels near .

In the impact test the amount of plastic deformation is characterized by lateral expansion. Lateral expansion is a thickening of the specimen during fracturing. Looking at half the failed .The amount by which the specimen deforms is measured and expressed as millimetres of lateral expansion. ASME B31.3 for example requires a lateral expansion of 0.38mm for bolting materials and steels with a UTS exceeding .

Up to a Charpy impact energy of 100J, the corresponding lateral expansion can be approximated by: LE(mm) = Charpy energy (J)/100 For higher Charpy energies, a fit to the data is given in Fig.1 .For each type of material, plot the lateral expansion versus the temperature. (All data) If possible, discuss the ductile-to-brittle transition temperature. Describe the fracture surface appearance .Shear and Lateral Expansion. Shear: Percent shear in a charpy impact test is a measurement of the amount of brittle and ductile fracture in a broken specimen’s fracture face. Lateral .

Lateral expansion is a measure of the ductility of the impact specimen. When a ductile material is impact tested, it will deform before breaking to create shear lips. The amount that the .Lateral expansion is a measure of the ductility of the specimen. When a ductile metal is broken, the test-piece deforms before breaking, and material is squeezed out on the sides of the compression face. The amount by which the .

In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .

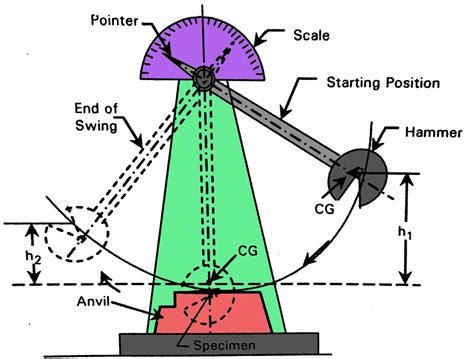

an impact test: lateral expansion and shear fracture appearance. Lateral expansion is a measure of ductility that corresponds to the increase in specimen thickness caused by plastic . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

what is a charpy impact

ultrasonic wall thickness measuring instruments

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and . Charpy’s early involvement with the notched bar pendulum impact test and his work toward standardization, this test is referred to throughout the world today as the ―Charpy‖ test. The original focus of the pendulum machine was on the measurement of absorbed energy [3, 4]. Other parameters from the Charpy test, in particular lateral .

What is the Charpy impact test used for? The purpose of the impact test is to assess the response of a known material, such as polymers, ceramics, and composites when subjected to sudden stress. It specifically evaluates the toughness, brittleness, notch sensitivity, and impact strength of engineering materials under high-rate loading. Quantifying the impact .MPM has developed a new technology for accurate shear and lateral expansion measurement. In addition, the system can be used for Charpy notch and other important dimensional verification. MPM has designed three optics and imaging systems to meet the needs of industry for accurate measurements on Charpy test specimens before and after impact .an impact test: lateral expansion and shear fracture appearance. Lateral expansion is a measure of ductility that corresponds to the increase in specimen thickness caused by plastic deformation (fig. 3, left). Shear fracture appearance is calculated as the ratio between the ductile (shear) portion of the fracture surface and the original

Lateral Expansion: Observing how much the specimen has expanded laterally can provide clues about its ductility. Greater lateral expansion generally signifies higher toughness. . Charpy Impact Test: Method: A weighted pendulum is released to strike a notched specimen. Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.

wall thickness measurement

Charpy Test The Charpy test is a good way to measure material toughness. It is useful for materials that exceed the 10.mm (0.394.inches) Charpy height. Specimens can also be made in ¾, and ½ sizes so in theory a 0.20 inch thick specimen can be produced. The Charpy specimen is relatively easy to make and test. The Charpy impact test is a commercial quality control test for . Us-ing the upper shelf energy test data it was also demonstrated the lateral expansion and impact toughness decrease simul . Conference: Charpy Impact Test Results on Five Materials and NIST Verification Specimens Using Instrumented 2-mm and 8-mm Strikers . Lateral expansion was measured for all specimens and the results are compared with the absorbed energy results. The overall results showed generally good agreement (within one standard deviation) in energy .According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant

Charpy energy (C V)–lateral expansion (LE) relations are useful in situations where a facility for measurement of LE is not available.In this note, after presenting the data for various steels in a single plot to get a global picture and discussing the dependence of the C V –LE plot on the type of steel, the data for particular classes of steels (austenitic stainless steels (SSs), . The specimens generally used for performing the impact test are: charpy specimen and izod specimen, both specified by ASTM E23 standard. Of these two, the type of cp (proof body) charpy type is the most used without a doubt. . Percentage of lateral expansion of the test body. The lateral expansion is the addition of the opposite face to the .

What is the Charpy Impact Test? How is the absorbed energy measured? . Lateral Expansion. The increase in the specimens width on the compression side, opposite the notch of the Charpy V-notch test piece. When to report the piece as unbroken. If during the test the test piece is deformed but not completely broken.In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral expansion, and percent shear fracture area. At present, the measurements of absorbed energy and lateral expansion are quantitative and well defined, but the methods used by most laboratories in the measurement of percent shear are qualitative at best.The response of direct metal laser sintering (DMLS) produced Ti6Al4V (ELI) to impact was investigated using an instrumented Charpy impact test machine and V-notch specimens.

Impact test: Energy Vs Lateral Expansion Impact test: Energy Vs Lateral Expansion marcolino21576 (Materials) (OP) 29 Sep 11 14:22. . Now, my accurate customer is rejecting the PQRs because project specification requires impact values expressed as "lateral expansion". Values found at PQR stage are about 100J, and my customer is requesting 0.38 .The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a). Lateral expansion is a measure of the ductility of the specimen. When a ductile metal is broken the test piece deforms before breaking, . The previous article looked at the method of Charpy-V impact testing and the results that can be .

How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .

Impact Test – A Charpy V-notch impact test is a dynamic test in which a notched specimen is struck and broken by a single blow in a specially design testing machine. The measured test values may be the energy absorbed, the percentage shear fracture, the lateral expansion opposite the notch, or a combination thereof.

Test criteria for Charpy V-notch impact testing usually involve (i) a minimum impact energy value, (ii) shear appearance of fractured test bars expressed in percent, and (iii) lateral expansion. For steels, the minimum acceptable values generally specified for these three evaluation methods are 20 J, 50 % shear, and 1.3 mm respectively.

Up to a Charpy impact energy of 100J, the corresponding lateral expansion can be approximated by: LE(mm) = Charpy energy (J)/100. For higher Charpy energies, a fit to the data is given in Fig.1. References. C S Wiesner, 'Toughness requirements for duplex and super duplex stainless steels'. Duplex Stainless Steels '97.Charpy V-notch impact test is used to determine the V-notch toughness of a metallic material according to the absorbed amount of energy for fracturing. . After the test the lateral expansion is measured, and expressed as a percentage increase in width from the original specimen size. The lateral expansion gives a further measure of the .

3.2.6 latched position, n—position of the pendulum on the release mechanism prior to being released to perform a test. 3.2.7 lateral expansion [L],n—the maximum increase in the thickness of the specimen as a result of the impact test, expressed in mm. 3.2.7.1 Discussion— Lateral expansion is used as a measure of ductility.

lateral expansion charpy

wall thickness measuring device

web26 de mai. de 2022 · ‘Top Gun: Maverick’ Review: Will This Stuff Still Fly? Tom Cruise takes to the air once more in a long-awaited sequel to a much-loved ’80s action blockbuster. .

what is lateral expansion in charpy impact test|charpy impact tester table